Japan Cell Co., Ltd. – Optical contact of adhesive free bonding process

- Company Name: Japan Cell Co., Ltd.

- State/Prefecture: Tokyo

- City/Town/Village: Machida

- Street: 2-2-5-11, Oyamagaoka

- Country: Japan

- Zip/Postal Code: 194-0215

- Phone: +81-42-798-4621

- Website: http://www.jpcell.co.jp/en/

- Contact: http://www.jpcell.co.jp/en/contact-2/

- Listed: 06/30/2014 4:28 am

- Expires: This ad has expired

Japan Cell serves leading-edge industry and research institute, providing the world’s best precision optical solutions for analytic, medical, bio-science, semiconductor and aerospace.

Our technology in fabricating high quality precision optics has become indispensable in today’s front-line industries, including electric products, automotive components, medical diagnostics and therapies, bio-technology and semiconductor manufacturing.

What is Japan Cell

Since its inception, Japan Cell has earned a reputation as a reliable manufacturer of superior quality precision optical components and today has enhanced state-of art bonding, polishing and coating capabilities providing a wider range of applications.

An early leader in the development of optical technology for the emerging high-tech industry, Japan Cell employs proprietary optical technology that enables the production of state-of-the-art precision optical devices used in a wide variety of products, including red blood cell counters, particle sensors used to count the number of particles in ultra-pure water and fiber couplers.

Japan Cell Technology

Optical Contact Technology

Optical Contact Technology

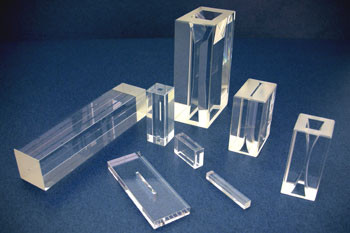

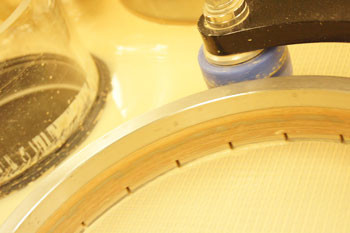

Optical contact of adhesive free bonding process is the core technology of Japan Cell. Optical contact is guaranteed solid bonded surfaces, Excellent flatness and optical surface quality, and No need to worry about elution problem from bonded surfaces. The product of Optical contact is widely used for laser analysis device and equipment, and Optical unit of UV Lighting source. Special Processing and Technology

Special Processing and Technology

State of the art polishing and finishing capabilitiesSince its inception, Japan Cell has earned a reputation as a reliable manufacturer of superior quality precision optical components and today has enhanced state-of-the-art polishing and finishing capabilities providing a wider range of applications. We have the expertise and manufacturing resources necessary to custom design, prototype and manufacture products based on the requirements of a specific project or need. Glass Welding by Gas

Glass Welding by Gas

Fusion bonding using gas burner requires long experience and exquisite craftsmanship. With or without lathe, various processes are enabled. Combination with optical contact expands process variety incredible. Glass welding by gas burner of Japan Cell is mainly to make Glass Cells. Tried and tested technology of glass cells can facilitate high precision works of gas inclusion, smooth glass tube surface and so on. Precision Polishing

Precision Polishing

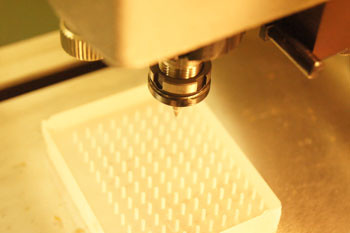

Japan Cell expertise in precision optical polishing process, which is a platform for developing state of the art optical contacts, enables the production of nano- and micro-structured surfaces. Optical contact processing involves a technique of polishing the contact surface to an exceptionally high degree, and is tuned to the quality of two contact plates that can vary from piece to piece. Optical Thin Film Coating

Optical Thin Film Coating

Japan Cell offers a variety of vacuum deposited thin film coatings for a wide range of glass, metal or crystalline substrates, including antireflective optical coatings, dielectric films, metal films and multi-layer optical stacks. The specific coating process and configuration varies with the desired level of performance and the substrate used. Precision Polish Inside Tubes

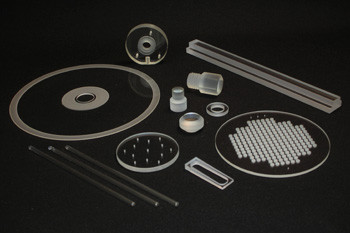

Precision Polish Inside Tubes

Quartz cylinder polished for visualizing inner combustion, various current, fluid flow, airflow inside an encasement (Specification : OD ±100μm x ID ±50μm) UV Bonding Technology

UV Bonding Technology

Two surfaces are bonded together with a bonding agent activated or cured by Ultra-Violet light at 350nm to 380nm. Japan Cell works UV bonding process at Clean room, and can prevent the entry of any contamination Photo sensitive adhesive is suitable for bonding glass surfaces having different heat expansion rate, and for bonding thin film coated substrates under ambient temperature. Ultra Violet cure also enables bonding glass and metal. Optical Assemblies

Optical Assemblies

State of the art bonding and alignment technologies combine with Japan Cell’s world-leading optics to deliver cost effective one-stop solutions. Japan Cell’s assemblies are produced within ISO Class 6 clean room, and ultra pure water 0.5m3/h RO water 0.5m3/h and inspissations water 0.5m3/h for exceptional contamination. Optical assemblies ensures optimal manufacturability. Low-Melting-Point Glass Frit Technology

Low-Melting-Point Glass Frit Technology

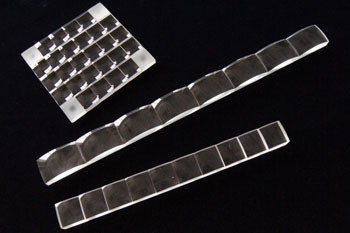

Glass frit is absolutely essential for encapsulating devices Nowadays, form a standpoint of decrease in burdens on the environment, glass frit has gotten a lot of attention for vacuum device, glass frit have gotten a lot of attention from LED light source, solar power generation and so on.

Glass frit bonding process is the core technology of Japan Cell too. Own prepared glass frit is tucked and fused at 600°between two glass surfaces. The bonded surfaces are highly chemical resistive and the method enables larger size of glass products. Glass frit bonding technology meets a broad range of customer needs.