Taiseiplas Co., Ltd – Manufacturing of original equipment for variety industrial fields

- Company Name: Taiseiplas Co., Ltd.

- State/Prefecture: Tokyo

- Street: 1-10-5, Nihonbashihoncho, Chuo-Ku

- Country: Japan

- Zip/Postal Code: 103-0023

- Phone: +81-03-3243-1851

- Website: http://taiseiplas.typepad.jp/e/

- Contact: http://www.taiseiplas.com/inquiry_e.html

- Listed: 05/30/2014 9:15 am

- Expires: This ad has expired

Business Lines:

- Researche, development and sales for synthetic resin treatment, and original equipments.

- Provision of expertise and technology relating to synthetic resin treatment

- Manufacture, sales, export and import of metal molds

- Acquisition, retention and licensing of patent rights

Application:

OA, Light electric parts, Telephones, Automobile parts, Swimming goggles, Fins for scuba diving, Super-low hardness elastomer mold products, Self-inking rubber stamp, Writing materials, Mobile phones, Peripheral equipment for personal computers, and etc.

Patents:

More than 300 applications for patents domestically and overseas. Taiseiplas is actively promoting the acquisition of industrial property rights, and etc. To make effective use of these industrial property right, Taiseiplas is actively expanding its licensing business.

We support the development of everyone’s products with technologies that only Taiseiplas can produce.

Product Development Service:

We offer total approach to product development with using our unique technology, experience and design strengths.

- Planning and Orientation

Unshackled by preconceptions, we start helping our customers by listening to what they say about the things they want made and the form they want these products to take. We propose various solutions by exploring the possibilities of technologies one by one, explaining item production, production costs and the choice of basic materials until we reach an agreement with the customer.

Unshackled by preconceptions, we start helping our customers by listening to what they say about the things they want made and the form they want these products to take. We propose various solutions by exploring the possibilities of technologies one by one, explaining item production, production costs and the choice of basic materials until we reach an agreement with the customer.

- 2D/3D design and Flow Analysis

No matter how complex the design, we aim to make to make it a reality. First of all, we transfer the sketched product to a 3D design using a cutting-edge CAD system. This is an indispensable process in the realization of the final product. Using this design data, we then apply a metal molding design, which creates a higher quality end-product.

No matter how complex the design, we aim to make to make it a reality. First of all, we transfer the sketched product to a 3D design using a cutting-edge CAD system. This is an indispensable process in the realization of the final product. Using this design data, we then apply a metal molding design, which creates a higher quality end-product.

Various techniques are used in order to properly realize the forms requested by our customers.

Flow Analysis

Flow Analysis

Based on flow analysis, it is possible to analyze the behavior of the resin that is injected into the metal mold using injection molding. The ability to estimate the distribution of the weld line, the flow pattern, resin pressure distribution, and resin temperature distribution means that we can prepare a more accurate metal mold. - Metal Mold Formation and Integration Molding

Our world-renowned proprietary metal mold and integrated molding technology, with more than 300 patent applications, is a strength for which Taiseiplas has earned the trust of its customers.

Our world-renowned proprietary metal mold and integrated molding technology, with more than 300 patent applications, is a strength for which Taiseiplas has earned the trust of its customers.

The main point of molded goods production is the advanced, complex knowledge and technology demanded when making a metal mold. In this area, Taiseiplas has universally-acclaimed, unique metal mold and single-body molding technology.

Various items injected and assembled with hard resins are high-quality, highly functional and low-cost products that have gained satisfaction and confidence from customers in many different fields. - Commercialization

Various products that realize manufacturing dreams are produced using our proprietary technologies. This is new type of crystallization connects with the next generation.

Various products that realize manufacturing dreams are produced using our proprietary technologies. This is new type of crystallization connects with the next generation.

Taiseiplas products include electronic communication equipment, automobile parts, items for living and miscellaneous goods, leisure supplies, medical and welfare apparatus, and stationery. Regardless of the type of product, we are proud to exceed the possibilities of traditional production practices. Next-generation functions, quality and design are visible at every turn.

Taiseiplas’s Technologies:

- Hard resin and soft elastomer joining technology

Using two-color molding or insert-molding, this joining technology for engineering plastic resins surpasses the inner-metal mold thermoplasticity and PC and ABS, etc. of elastic rubber and metal molding processes.

Advantages:

Reduction of production costs and component parts

Greater reliability of material quality

Reduced cost, and recyclable - Elastomer and metal joining technology

The surface is coated with a special paint (ink) and is stiffened by inserting the injection mold. This joining technology inserts TPE (thermoplastic elastomer). It is available for a wide range of products, such as PDAs, mobile phones, barcodes, liquid crystal displays, liquid crystal display panels, and protective cushions.

Advantages:

Rationalized manufacturing process - Resin and aluminum alloy joining technology (NMT technology)

This technology produces integrated aluminum alloy and resin products by inserting a metal injection mold in aluminum-pressed products using PBT or PPS resin.

Advantages:

Designed to be super-lightweight and thin to add value

Provides alternative to metal casting, etc.

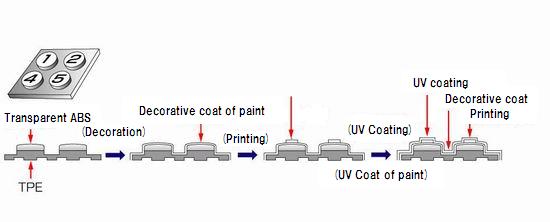

Simplified manufacturing process - UV coating technology for products molded from hard resin and thermoplastic elastomer

Decorative painting and UV surface coating for 2-color molded products made from hard resins such as ABS and PC and TPE. (For use in products such as jack covers, terminal caps, and earphone caps) There is also decorative painting using TPE substance + UV coating technology.

Advantages:

Coating without need for masking, low-cost key sheet

Improved added-value, design and functionality - Joining technology for automatic insertion of metal injection mold to automatic feeding/disconnect of resin mold product assembly and injection of different resins

When a keytop assembly is molded at once and then loaded into a stocker, the insert machine will automatically cut off and insert the metal mold into the necessary parts (individual keytops). Inserting the TPE here enables the keysheet to perform automatic molding.

Advantages:

Mass production-oriented