Eco-Stage Engineering Co., Ltd. – Produces Valuable Resources from Organic Waste

- Company Name: Eco-Stage Engineering Co., Ltd.

- State/Prefecture: Fukuoka

- City/Town/Village: Fukuoka

- Street: 3-19-14 Hakata Ekimae, Hakata-ku

- Country: Japan

- Zip/Postal Code: 812-0011

- Phone: +81-92-409-5850

- Website: http://www.eco-stage.com

- Contact: info@eco-stage.com

- Listed: 08/04/2014 4:51 pm

- Expires: This ad has expired

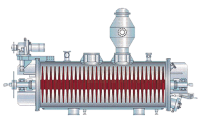

Our company’s patented technology “oil temperature decompression drying device” dries various kinds of organic waste with high water content in a short period of time, and is technology that produces valuable resources. Currently, approximately 80,000 tons of food residue from business are processed at this plant annually in Japan, which is then distributed as a little less than 20,000 tons of blended feed materials.

Our Technology

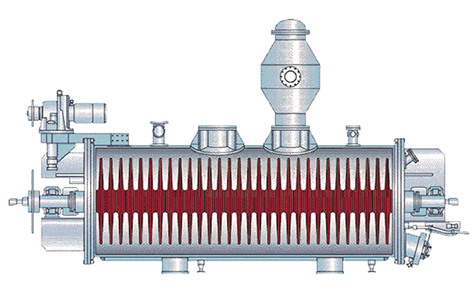

The “oil temperature decompression drying technology (tempura method)” is unique patented technology that uses waste cooking oil as an indirect heating medium to mix and heat organic waste with dewatered sewage sludge and food waste, lower the boiling point by reducing the pressure inside the device to an atmospheric pressure of approximately 0.6, and vaporize the treated material at approximately 85°C to 110°C.

As a result of the water vaporizing, the input waste is reduced to approximately 1/5 to 1/3 its original amount, and the water content falls to less than 5%. Although usage methods for the product material that underwent drying differ depending on the waste, the product material can be reused as valuable resources. In the case of sewage sludge, the product can be used as fuel for mixed combustion at thermal power plants, and in the case of food waste, the product can be used as feed and fertilizer.

Our Strengths

- Uniform drying is possible in short-term drying treatment

Since drying is carried out under reduced pressure using oil as a drying heating medium, the oil and organic waste that is subject to treatment come in contact evenly, and the water content of the product material after drying is “uniform” everywhere.

In addition, by forcing the water to vaporize by reducing the pressure, highly-efficient and rapid vaporization is possible. - Organic waste is reproduced into valuable resources and effectively used

Since drying is carrying out based on “frying” using waste cooking oil, a certain amount of waste cooking is contained in the product material after processing. This gives new added value to the product material that is not possible with normal drying technology, enabling for valuable sale and reuse.

For example, in the case of sewage sludge, the oil that is contained due to processing increases the caloric value, and becomes product material with an average particle radius of approximately 1mm, with a high lower heating value (about 25Mj/kg) that is approximately the same as that of coal. This can then be effectively used in fuel for mixed combustion at thermal power stations.

In addition, in the case of food waste, most of the organic nutrients are recovered and sterilization is also carried out at the same time, enabling for product material with high added value as feed and fertilizer

to be produced.

Comparison of solid fuel processing of sewage sludge

| Carbonization | Granular drying | Oil temperature decompression drying |

|

| Heat value (MJ/kg) | 9.6-14.6 | 14.6-18.8 | 23.0-25.1 |

| Water (%) | ca. 5 | ca. 6-10 | ca. 3 |

| Ash (%) | ca. 50 | ca. 30 | ca. 20 |

| Bulk specific gravity | ca. 0.4 | ca. 0.6 | ca. 0.6 |

| Odor | none | strong | weak |

Intended uses/Anticipated users

- This technology is used in plants throughout Japan where food residue, sewage sludge, night soil, and residue from food processing plants are treated, and enables for various organic waste and unused biomass to be turned into feed, fertilizer, and fuel.

- This technology has been gaining attention overseas, as demonstrated by many inquiries from people in China and Korea who have difficulties processing food waste in particular.