Ogic Technologies Co.,Ltd. – Surface Finishing Technologies

- Company Name: Ogic Technologies Co.,Ltd.

- City/Town/Village: Kumamoto

- Street: 2-9-9 Kamikumamoto

- Country: Japan

- Zip/Postal Code: 860-0079

- Listed: 02/01/2013 11:04 pm

- Expires: This ad has expired

At Ogic Technologies Co., Ltd.(OGIC) we conduct surface finishing for metal and ceramic components of a wide variety, such as semiconductors, electronic devices, semiconductor production equipments, industrial robots and automobiles.

OGIC QA System

OGIC QA system is based on ISO9001.

We are always taking new ideas in order to satisfy to customer requirements.

By this reason, we are able to take the new ideas such as QA net work system and Small noticed change control , and have been introduced to partly run, tentatively from previous year.

Line up of leading surface technology

- OGEP: EP(Electric Polishing) Processing

EP coating applicable to aluminum and stainless steel (austenite and martensite) materials. Can be used for semiconductor production equipment components to control emission gas, which generates during vacuum procedures. Especially in our process, there is no generation of corrosive[S] gas as in the conventional process. - O-DENT: Light etching to reduce Electrostatic charge

This surface finishing can make many micro and sharp projections on the aluminum surface by a special wet etching. It is useful for reducing static electricity electrification between a glass substrate for FPD and a mount stage of FPD production equipment. - NIPOLYN: PTFE compounded electro-less Ni plating

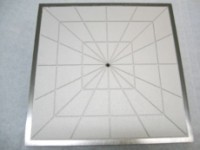

Electroless nickel plating, Composite (PTFE composite plating) a nickel – phosphorus alloy is an abbreviation of the designation. Polytetrafluoroethylene [PTFE] non-adhesive water repellent, low wear, high hardness of electroless nickel plating power is combined with the performance of both plated and macrothrowing power. - Electro forming; for MEMS (Micro electro mechanical systems)

Circuit pattern plating of 75-100μm

Plating thickness of Over 200μm

Our Website: www.ogic.ne.jp/english.html