Kenki Co., Ltd. – Sludge Waste Dryer

- Company Name: Kenki Co., Ltd.

- State/Prefecture: Fukuoka

- City/Town/Village: Fukuoka

- Street: 3-9-7 Kamimuta, Hakata-Ku

- Country: Japan

- Zip/Postal Code: 812-0006

- Phone: +81-92-411-1203

- Website: http://www.kenmori.com

- Contact: info@kenmori.com

- Listed: 07/15/2014 8:38 pm

- Expires: This ad has expired

Our company’s drying equipment dries raw materials in a sludge or slurry state with high adhesiveness, which is traditionally difficult to dry, and can be used for raw materials, fuel, ingredients, foodstuff, fertilizer, etc. This dryer has attracted lots of attention both within and outside of Japan, and we are looking for companies that would like to cooperate together with us in business expansion overseas.

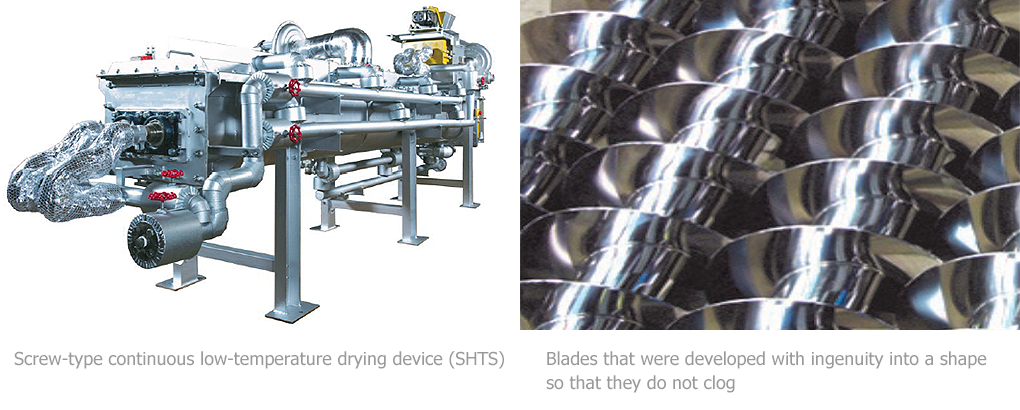

Sludge Waste New Dryer – “SHTS” (Steam Heated Twin Screw)

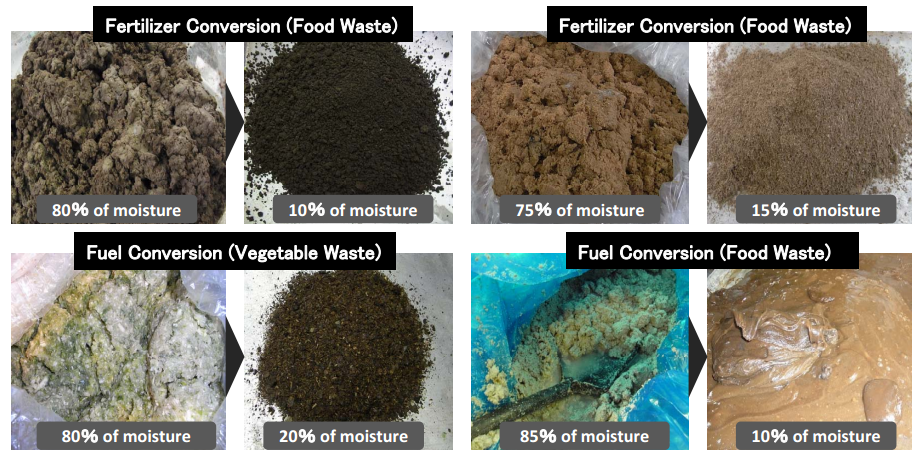

- Dries sludge and waste for use as fertilizer, compost, feed, or fuel.

- Waste can be recycled into fuel because its composition does not change through the low-temperature drying process.

- Able to dry chewing gum, starch syrup or caramelized type foods without causing it to stick to, or clog the equipment.

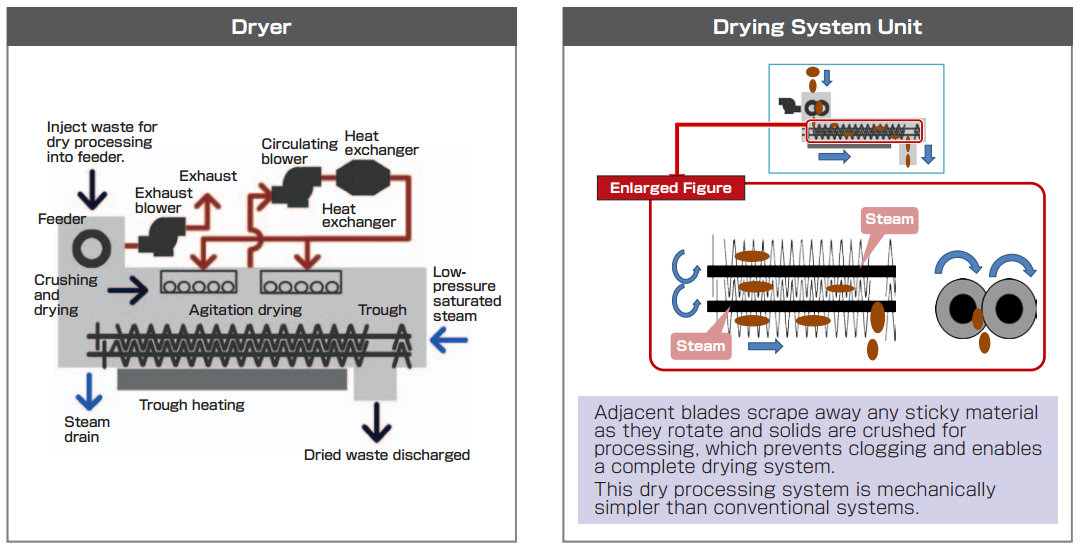

- Low-pressure steam drying is at least three times as efficient as hot-air drying. The process is also safe because there is no direct use of fire.

Overview of Product / Technology

- Product Function

Reduces water content in sludge, food waste, or other wastes to allow for use as fertilizer, compost, feed, or fuel. The low-temperature drying process using low-pressure steam is safe and does not change the composition of waste, consequently recycles waste into fuel. - Product Features

Special blades turn while intersecting with each other to agitate and dry waste. Adjacent blades scrape off waste stuck on the primary blades, so any sticky waste can be dried without clogging the dyer. Solid waste is crushed and dried simultaneously. - Examples of Application

Drying high water content liquid-like sludge. Dry food waste that would otherwise stick to and clog conventional dryers. Able to crush and agitate solid objects such as cores of cabbages.

Detailed Information on Product / Technology

- Maximum pressure of low-pressure steam introduced from the drying heat source: 0.7 MPa

- Maximum amount of waste to be dried that can be introduced, assuming that the water content of waste is 80% before drying and 20% after drying and 0.5 MPa of steam pressure is introduced:

Maximum amount of waste that can be injected per system:

500 kg/hour (1 ton/hour for 2 systems; 1.5 tons/hour for 3 systems)

Overseas Distribution

- Development, design, manufacture, installation and maintenance of all industrial machinery and equipment

- Environmental machinery and equipment Waste dryers, organic waste-to-fuel conversion systems, deodorizing systems

- Sludge dryers delivered to: Toyota Auto Body, Mitsubishi Electric, Kawasaki Heavy Industries

- Products exports to South Korea Food waste dryers