Japanese printing manufacturer, Toppan Printing developed the copper touch panel module with ultra-narrow bezel

Development of a copper touch panel module with ultra-narrow bezel

Date: June 2, 2015

Source: Toppan Printing Co., Ltd.

– Narrower bezel and reduced weight enabled by adopting copper wiring and a high-rigidity plastic cover –

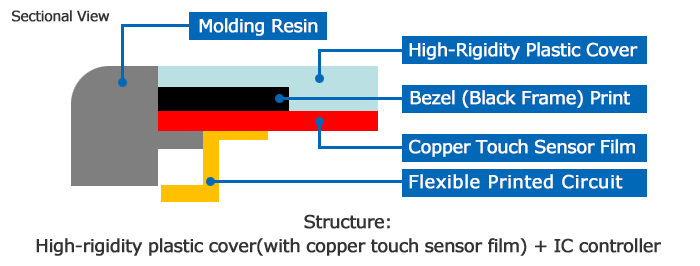

Toppan Printing Co., Ltd. (hereafter Toppan Printing; Head office: Chiyoda Ward, Tokyo; President & Representative Director: Shingo Kaneko) has developed a copper touch panel module with which the use of copper wiring and a high-rigidity plastic cover resistant to bending and impacts has enabled a significant decrease in weight and an ultra-narrow bezel. This means that the product can be smaller, maintaining the same screen size while enhancing the possibilities for innovative design. Sample shipments will begin in mid-July 2015, predominantly targeting use in tablets and notebook PCs.

With this product, the adoption of low-resistance copper for the touch sensor film electrode material has made single routing possible and drastically reduced the number of wires required. Toppan’s cutting-edge etching technologies have also enabled a finer wiring pitch.

In addition, cover glass has been replaced with a high-rigidity plastic cover, which is resistant to bending and impacts, enabling a weight reduction of about 40% when compared to glass of the same size (area, thickness).

During SID Display Week 2015 (May 31 to June 5), this product will be exhibited and demonstrated from June 2 to 4 at the Toppan Printing and Ortus Technology booth (#1546) at the San Jose Convention Center, California, USA.

Background

There is always demand for smaller and lighter tablets and notebook PCs. ITO (Indium Tin Oxide) is used as the electrode material for the cover glass in the touch panels of the majority of such devices, but its high resistance means that lead wiring is required on both sides, and it has therefore been difficult to make the bezel narrower.

To address this issue, Toppan Printing utilizes copper, which has low resistance. This has made single routing possible, significantly reducing the number of wires, and enabled a copper touch panel with an ultra-narrow bezel to be developed by employing cutting-edge etching techniques. The narrower bezel contributes to making the product casing more compact, and a drastic weight reduction is also achieved by using a high-rigidity plastic cover.

As exterior parts and the touch panel module can be integrated into a single body in any form due to these of the in-mold method, high-quality design is possible, especially for tablets and notebook PCs.

Copper touch panel module with ultra-narrow bezel (left) and the conventional product (right)

Features of the coppertouch panel with ultra-narrow bezel

- Reduction ofcasing size enabled by ultra-narrow bezel

Single routing is achieved and the number of wires hasbeen reduced significantly by using copper, which has low electricalresistance, as the electrode material. A finer wiring pitch has enabled thedevelopment of an unprecedentedly narrow bezel and contributed to a reductionin the size of the product casing. A minimum bezel width of approximately 3.4 mmis possible for mid-scale models of more than 10 inches. - Weightreduction made possible by high-rigidity plastic cover

The use of a plastic cover with high rigidity enables a weightreduction of approximately 40% compared to glass ofthe same size (area, thickness). Safety is alsoensured by laminating the plastic cover and copper touch sensor film together tomake the cover shatterproof. - Exterior partsand touch panel module integrated into a single body using in-mold formingmethod.

Inaddition to the reductions in size and weight, exterior parts and the touchpanel module can be integrated into a single body, something made possible withtechnical assistance from Wonder Future Corporation (Head office: Yokohama, KanagawaPrefecture; President & Representative Director: Koki Fukuda). This featureenables innovative design.

Click image for enlarge.